Around four years ago, I had to lay down my screwdrivers and take up residence in hospital for back surgery. That shouldn't have been a problem, usually 3-6 months later and it's back in business. Except in some cases that is, and unluckily for me I turned out to be one of those "some cases". Well, fourteen major back surgeries later, including a stint in ICU in a coma on life-support (I regret to say I can't remember seeing any tunnels of light!), I am at last back home and able to spend a few hours a day at my workbench, thankful that I can even walk to it. I am very grateful to be alive after going through all that, in no small way due to the unrelenting help and support of my Thai wife Siri.

I have serviced plenty of Omega cal 321 Speedmasters before, but I have never actually owned one, and they have always been a favorite of mine. Definitely a watch on my "must get one day" list. So when I read the late Chuck Maddox's article on "What watches were worn on or near the moon", it was enough to push me the extra step to owning one. At the time of the moon landing, the Omega 321 Speedmaster was the only watch certified by NASA for space flight. So, on the surface it seems quite odd that the actual model of Speedmaster worn on the moon is called a "pre-moon" Speedmaster. Although the cal. 861 Speedmaster had already been released at the time of the moon landing in 1969, it is thought unlikely they would have filtered through to NASA by 1969, let alone be certified for space flight. And, being the Speedmaster currently available in 1969, it naturally became the model that ended up being known as the "moon watch". Of course, when Omega found out that the Speedmaster was being used by NASA, their marketing department was quick to action and many 861 casebacks were engraved "The First And Only Watch Worn On The Moon". However, they came to understand that even though the Speedmaster was the first and main timepiece used in the moon landings, in following years astronauts brought others to the moon as personal backups. So, later casebacks reflected this with the engraving suitably modified. Well, I am not too worried about that little faux pas, simply being the first is something to brag about. No other watches made it through the rigorous testing for flight certification.

So, laying in my hospital bed loaded up with pethidine and plenty of time to think, the idea occurred to me that it would be much nicer to have a brand new or NOS 321 Speedmaster, rather than a used one. Only problem is that they have been out of production for more than forty years. Would it be possible to make one from spare parts? No problem if all the parts can be found. As it happened, I had converted all my service manuals to pdf files in case I got watch withdrawal symptoms while in hospital, and I had them on my notebook (I also had some favorite watches with me too, to help keep me company). So I set to work to build up a complete parts list of what I would need. That isn't as easy as it sounds, as the Omega 321 parts manual starts with the 27 Chro from its inception in 1942, and progresses stage by stage through the various versions of the 27 Chro, to the 320, and up to the latest 321 - there being no single absolute list of 321 parts as such. There are many common parts from step to step (eg. a 320 barrel is not the same as a 321 barrel, but the reset hammer for a 320 is the same as a 321 reset hammer etc.) so it was a real exercise to do, and took a long time. There are a total of six variants of this movement. Having done that, I set about trying to source the parts, and for a while it looked like I was not going to be able to get everything. To cut a long story short, it took three years and dozens of emails and phone calls to suppliers all around the world. I finally thought I had everything I needed to complete my project. If you think I got it right first time - no way! - it took many re-orders to correct my mistakes, and I ended up with lots of extra parts that I wouldn't need. Of course, as I got closer and closer to a complete set of parts, I became quite anxious, picturing in my mind having all but one special unobtainable part which would stop me from finishing! And it is true, many 321 parts really are very hard to get, but I was lucky in the end.

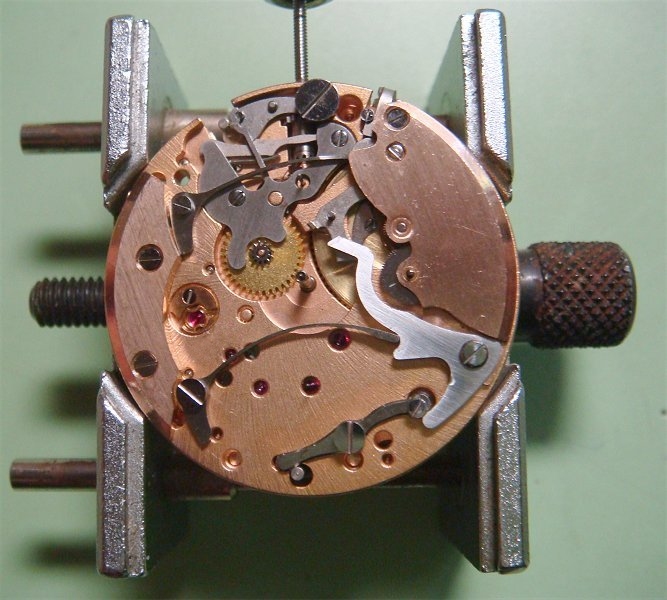

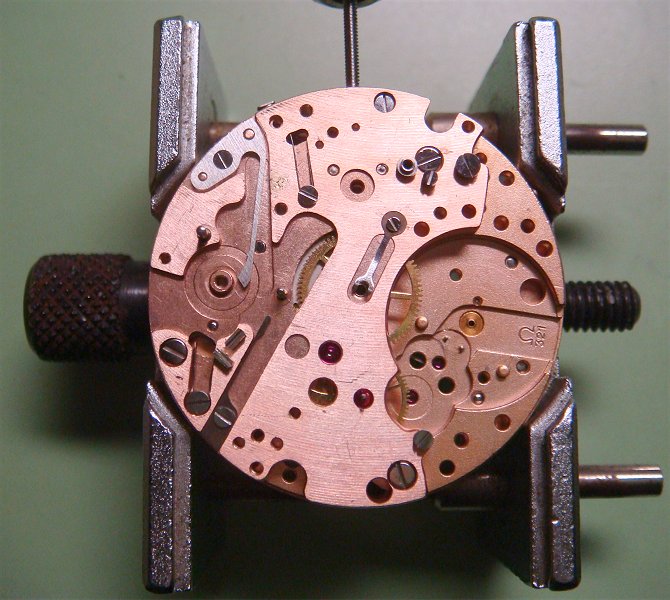

It was quite some time after I finally got back home from hospital before I had all the parts, but I needed time to recover anyway. The following series of pics gives a rough idea of how my project progressed. Excuse their quality, I'm no Paul Delury!

In summary, there are questions one might ask about this project. Was it easy? What it worth the trouble? Was it a cheap way of getting a nice watch? Would I recommend it is a project for others to do?

Though I really like the 321 movement, some people believe the cal. 861 is perhaps a better movement overall. For many chronograph lovers like myself, the column wheel mechanism is a very important part of the mystique of this type of watch, and even if the cam lever system of the 861 has a nicer feel to it, that doesn't really matter to me. The 321 has history and character, being the first watch worn on the moon, and that to me is a big plus in its favor regardless of anything else.

For myself, this project served a major purpose. It kept me occupied and gave me something to look forward to doing while I spent years on my back in bed. For just that alone, it was well worthwhile. As for cost, I reckon I could have bought two or three nice second-hand 321's with what the parts cost alone. I would not recommend this as a "fun project" for a few reasons. You need some really friendly parts suppliers who know you well. The chances of getting everything you need is low. You need reasonable watchmaking skills and a good selection of tools. It is not simply a matter of screwing together all the bits, tolerances vary and often parts need tweaking to fit properly. I am sure this would have occurred in the Omega factory too as the watches progessed down the assembly line. Despite the high precision in the manufacture of watch parts, sometimes tolerances add up the wrong way and something is either too loose or too tight and needs adjusting or a replacement part is needed. As they say on "Funniest Home Videos"..."Don't Try This At Home!"

I hope you enjoyed reading about my little project. I have only one regret. Chuck Maddox was looking forward to seeing the completed watch, and I am sad to say I didn't get to finish it in time.